CAD-CAM CUTTERS

High quality burs for PMMA, wax, peek, presintered Cr/Co and zirconia. They are also compatible for Amann Girrbach, Roland, Sirona, VHF, Zirkon Zahn milling machines.

Although not present on the site, compatible cutters are available on request for the following CAD/CAM systems: 3M Espe Lava, Cercon, Arum, Dentium, Imes-Icore 240/250, Imes-Icore 350/550/750, Kavo, Sirona Cerec, RK, Wieland Mini, Wieland S1, Yena, DentalPlus, IdealMill, Up3d P5, Upcera X5, Xtcera XT-220, Xtcera XT-500.

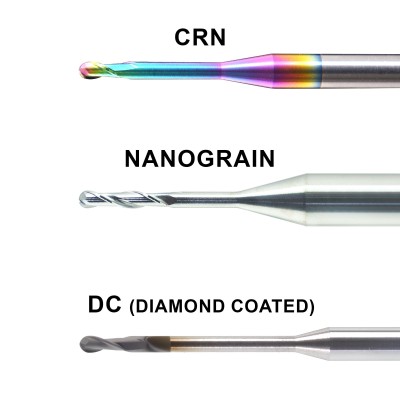

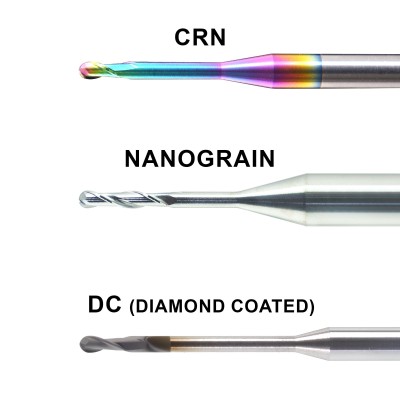

CUSTOM. Available in CRN (for PMMA, Peek and wax), NANOGRAIN (for zirconia) and DC (for zirconia) models.

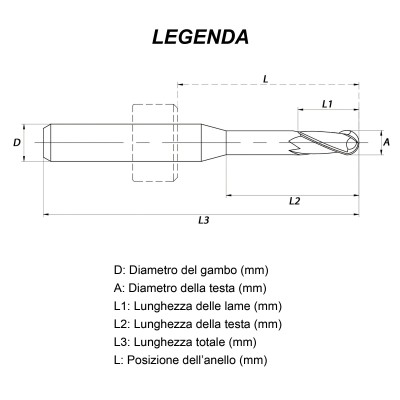

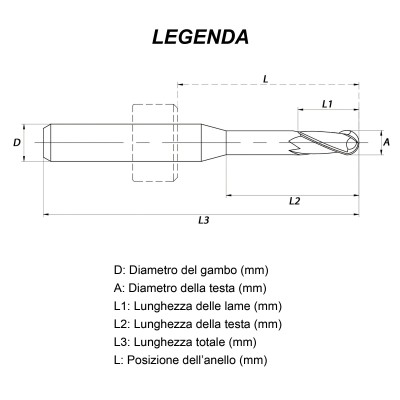

Dimensions: A 0.6 - L1 1.5 - L2 6 - L3 50 - D 4 (see legend photo)

CRN

- CRN model (for PMMA, Peek and wax)

The CRN (chromium nitride) treatment makes the surface harder and smoother, greatly reducing friction and heating, thus increasing durability. They are ideal for milling PMMA, as they tend to heat less and do not knead. They are suitable for machines that mill both wet and dry.

NANOGRAIN

- NANOGRAIN model (for zirconia)

These cutters are made from the unique NANOGRAIN tungsten carbide which gives CAD/CAM cutters a sharp milling edge and very high wear resistance. In addition, our NANOGRAIN cutters, which have a higher hardness than ordinary DLC (Diamond Like Carbon) coating, can effectively reduce defects caused by improper coating procedures and increase the quality of work pieces.

DC

- DC model (for zirconia)

The DC (Diamond Coated) treatment is a treatment commonly called "diamond" that makes the surfaces of the cutters extremely hard and very resistant to wear. This treatment is not to be confused with DLC (Diamond Like Carbon) which is less performing. There is currently no surface treatment that makes the world's most durable cutters.

Data sheet